Repeat visits are more than just a scheduling headache—they’re a sign your service operation is misfiring. And in today’s margin-tight environment, you can’t afford that.

And neither can your customers.

As client expectations climb and skilled labor becomes harder to find, first time fix rate (FTFR) has become a defining metric in field service.

But improving FTFR isn’t just about sending better techs or buying better tools. It’s about aligning service teams and tools

Customers today expect Amazon-level service from every brand—including yours. They don’t care how complex the job is. They want it fixed. Fast. And right the first time.

Your C-suite is just as demanding.

You’ve invested in artificial intelligence (AI), field service management (FSM) tools, and training programs.

So why hasn’t your FTFR moved?

Maybe the problem isn’t just more tactics, tech and tools—it’s better orchestration.

Where Do You Stand Today?

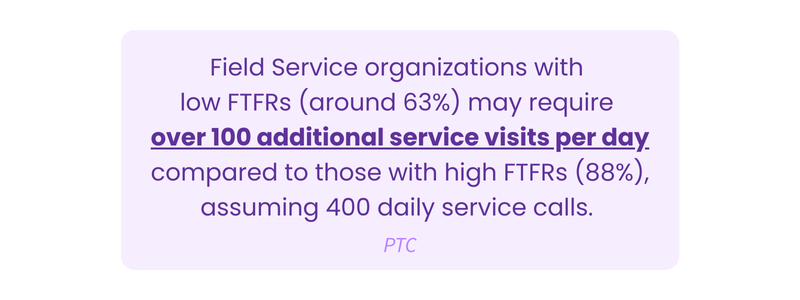

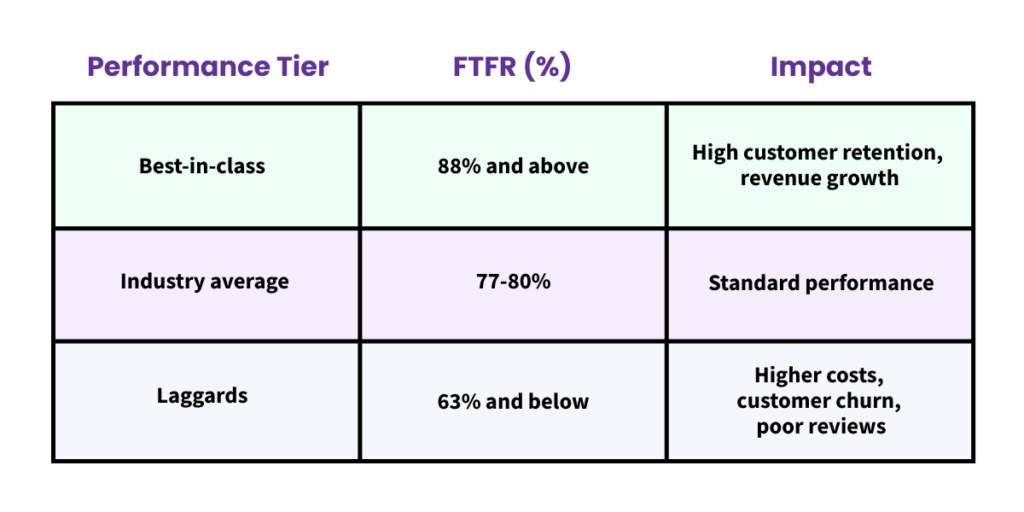

Before we dive in, here’s a quick check to see where you stand among your peers. Of course, these numbers will vary by industry, but this will give you a sense of the ballpark.

Better orchestration could help your techs fix 15–20% more jobs on the first visit—without working harder.

We think it’s possible… and it all starts with a shift in how you manage those parts, people, processes, and proactive technology.

The Right Part at the Right Time

“Without the right part, even your best tech can’t save the day.”

It’s one of the oldest frustrations in field service: a technician shows up ready to work, but the fix can’t happen because the right part isn’t in the van.

It’s not a skills issue. It’s not a customer issue. It’s a parts issue.

And it remains one of the most common causes of repeat visits, costing time, money, and customer trust.

But here’s the good news: this is also one of the most solvable problems—especially today.

A New Era of Parts Readiness

Service parts management used to be reactive and manual. Technicians carried generic van stock, relying on best guesses or tribal knowledge to prepare for jobs. Inventory systems weren’t connected to field operations, and procurement was often an afterthought.

That model doesn’t work anymore—not with today’s complex equipment and razor-thin service-level agreement (SLA) windows.

Thanks to modern technology and smarter field service processes, we live in a time where predictive, data-driven parts readiness is possible—and necessary.

Here’s how leading service teams are ensuring their techs show up fully equipped:

AI-Driven Parts Prediction at Intake

Modern systems use historical job data and machine learning to predict what parts are most likely needed for a specific issue. If a customer reports a recurring error code, your system can match that to past jobs, identify the required components, and recommend a parts kit—automatically. This replaces guesswork with data.

Instead of relying on what “might” be needed, you’re using patterns to predict what “will” be needed.

Real-Time Inventory Visibility for Dispatch

Inventory systems are no longer siloed. Connected field service platforms allow dispatchers and planners to see (in real time) what’s in each technician’s vehicle, what’s in the warehouse, and what’s in transit. This helps ensure the right tech is sent with the right parts and can even trigger auto-replenishment for high-use items.

Dispatchers can stop playing logistics detective—they get instant clarity on availability.

Pre-Dispatch Visual Inspections to Confirm Parts

Before a tech ever rolls out, remote support tools allow your team to see the issue firsthand. A quick video call with the customer can verify what’s broken and which part is needed—especially useful in scenarios where symptoms can be misleading.

A 5-minute visual check can prevent a costly return visit and wasted drive time.

Standardized Part Kits for Common Jobs

Build kits for the most common repairs and align them with technician roles and territories. These can be stocked based on seasonal patterns, geography, or equipment type. Smart automation ensures these kits stay replenished based on usage, not guesswork.

Think of it like a pre-packed toolkit for success—tailored by data.

Diagnosing and Dispatching with Precision

“First-time fix starts long before your tech hits the road.”

Field service success starts the moment a service request comes in. And too often, the front-end of that process is broken.

Historically, job intake has been unstructured. A customer calls in, describes a problem in layman’s terms, and the service coordinator logs it in shorthand or a free-text field.

“Unit not working” or “machine down” becomes the job description.

With that vague starting point, dispatch is flying blind.

But that’s changing.

A Smarter Approach to Service Intake and Dispatch

Modern service organizations are evolving from basic call logging to intelligent triage and dynamic dispatching, using data and automation to improve job accuracy—and FTFR.

Here’s how:

Structured Intake with Smart Forms

Use guided intake forms instead of open-ended text boxes. These forms ask specific questions in a logical order, making it easier for customers to give the right information. With AI, the forms can adjust on the fly — asking follow-up questions based on what the customer says. This improves accuracy and ensures you get consistent, useful data for diagnosing issues and analyzing trends.

A clear problem description means fewer surprises for the tech—and higher odds of a fix on the first visit.

Remote Visual Triage to Confirm Job Scope

Before scheduling, use remote video support to confirm the issue. This adds clarity and helps triage whether the issue requires a field visit, can be resolved remotely, or needs specialized tools or parts.

It’s like doing a “virtual walkthrough” of the job before committing boots on the ground.

Integrated CRM + FSM Systems for Contextual Dispatch

Modern platforms integrate customer records, asset history, and past service data. Dispatchers can make better decisions about which technician is best suited for the job based on skill, proximity, or equipment familiarity.

The more context your scheduler has, the better they can match the right tech to the right job.

Skill-Based Routing and Job Escalation Protocols

Automatically match jobs to techs with the specific certifications, past experience, or OEM knowledge needed. Escalation workflows ensure complex jobs get flagged and assigned accordingly—not left to a generalist unprepared for a niche issue.

Precision dispatching reduces both service costs and resolution time—while lifting FTFR.

Equip Your Workforce for the Field

“Empowered techs don’t just fix more—they fix smarter.”

It’s no secret: there’s a widening experience gap in field service. As veteran technicians retire, a wave of newer, less-experienced hires is stepping in. But the tools, machines, and software they face in the field have only gotten more complex.

Traditionally, technicians learned on the job—shadowing seniors, swapping war stories, and building muscle memory. That approach no longer scales. Today’s service leaders need to institutionalize tribal knowledge and boost technician performance across the board.

Here’s how to create a team of consistent, capable fixers:

Real-Time Expert Support via Video

Don’t let techs get stuck mid-job. Equip them with live video tools to call on remote experts in real time. Senior specialists can guide repairs —no return visits needed.

Your tenured techs become coaches-on-demand, extending their impact without ever leaving the office.

Visual Repair Guides and AR-Enhanced Instructions

Gone are the days of flipping through thick manuals. Field techs now rely on step-by-step visual instructions delivered via mobile apps or smart glasses. AR overlays show them exactly where to look, what to check, and how to proceed.

This shrinks the learning curve and reduces the risk of trial-and-error.

Just-in-Time Access to Service Intelligence

Give techs mobile access to asset histories, previous work orders, service bulletins, and known issue resolutions. Contextual knowledge equals faster, smarter decisions.

When a tech understands the full story, they troubleshoot with confidence and clarity.

Performance Analytics and Coaching Programs

Don’t just measure FTFR—analyze it by individual. Identify who consistently performs well and who struggles. Use that insight to deliver targeted coaching, training, or tool upgrades.

Data-driven training ensures your weakest techs don’t stay that way for long.

Turning AI & AR into Field Force Multipliers

“Technology should make every tech your best tech.”

The field service toolkit has evolved. Clipboards and pagers have given way to tablets, smart wearables, and real-time remote support. But it’s not the tools themselves that matter—it’s how well they’re connected and applied.

Today’s top-performing service orgs aren’t just using technology—they’re orchestrating it. The goal isn’t more tools. It’s smarter, frictionless workflows that proactively prevent problems, streamline service, and raise every tech’s performance.

Here’s how to turn your tech stack into a service multiplier:

AR and Visual Assistance for Complex Repairs

Use AR tools to guide technicians through repairs with real-time overlays, 3D diagrams, or animations. Whether they’re in the field or a factory, techs get visual prompts layered onto the equipment.

The repair process becomes interactive and intuitive, even for fresh hires.

Seamless System Integrations

Your CRM, FSM, knowledge base, and remote support tools should work in harmony. A disconnected tech stack leads to delays, data loss, and frustration. Ensure systems talk to each other so techs don’t waste time toggling between apps.

When systems are connected, your people stay focused on the fix—not the friction.

Predictive Maintenance Using IoT and AI

The most powerful FTFR strategy? Prevent the failure before it happens. IoT sensors can track machine performance and trigger alerts when issues are brewing. AI then analyzes that data to recommend proactive service.

It’s not just fixing things faster—it’s reducing the need to fix them at all.

Technician Dashboards and Job Prep Tools

Equip every technician with a “day-of” dashboard showing job locations, expected issues, required parts, safety notes, and digital checklists. The more they know going in, the faster they work—and the fewer return visits they’ll need.

It’s like giving every tech a service concierge to prepare them for success.

Ready to Build Your FTFR Game Plan?

Improving first time fix rates doesn’t happen overnight. But with the right structure—Parts, Process, People, and Proactive Tech—you can move the needle faster and with greater impact.

Here’s a quick self-check to start:

- Are your techs arriving with the right tools and parts?

- Is your intake process giving dispatch everything they need?

- Can your junior techs get expert help instantly?

- Are your systems and tools working with each other—not against?

Field service leaders who invest in these four pillars see the difference not just in service costs, but in happier customers, more confident technicians, and fewer return visits.